Expansion Joint Design Considerations

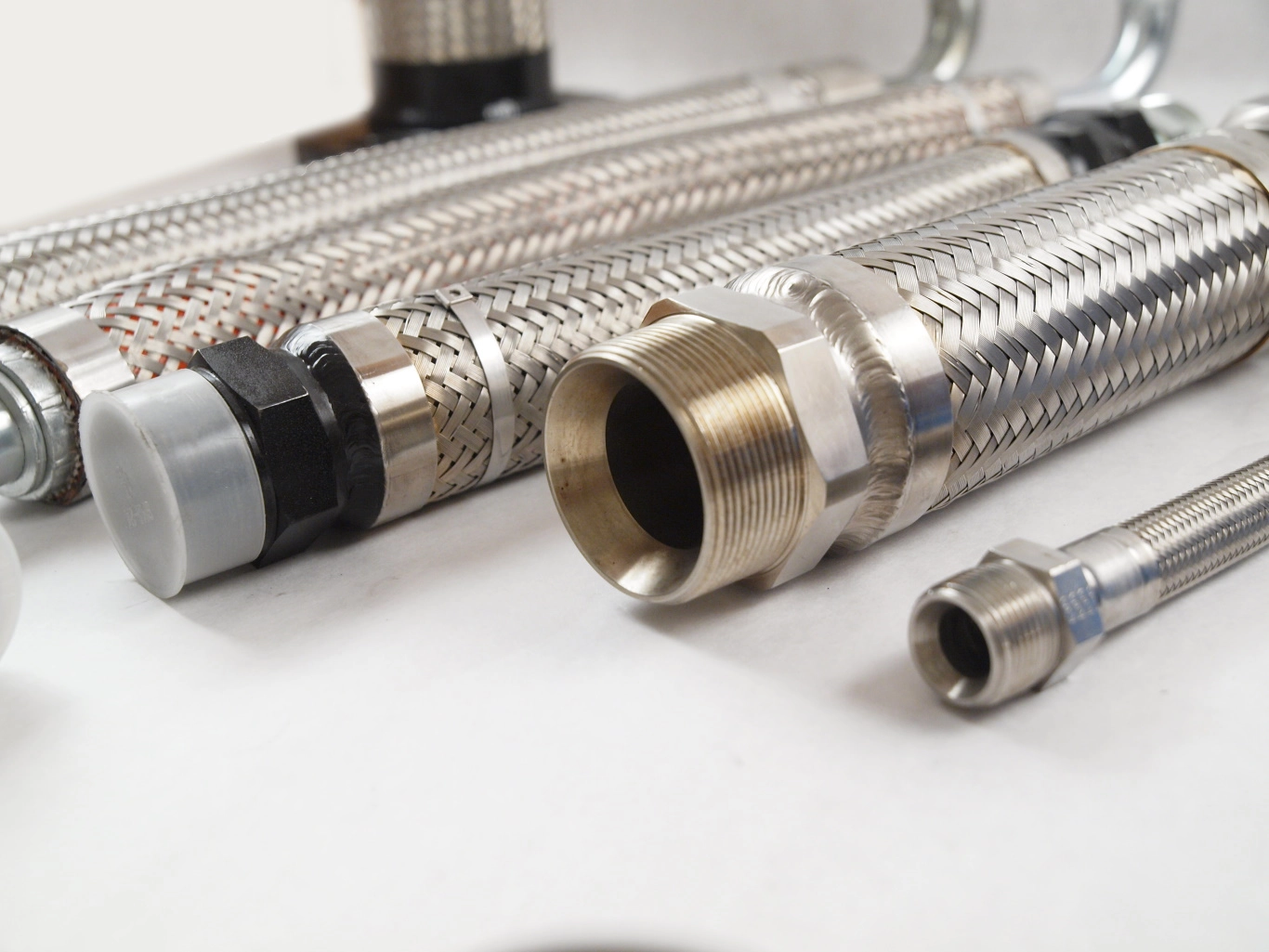

When designing an expansion joint, many factors are to be considered. An expansion joint ( specially a stainless steel expansion joint ) is a customized product and needs to be designed based on a particular application. The performance and life of an expansion joint will improve significantly if the right expansion joint is designed and installed for the application. The following parameters are taken into consideration when designing an expansion joint :

Design Standard

Expansion Bellow Material

Bellow Design Pressure and Design Temperature

Movement

End Fitting specification

Inner Sleeve

Insulation Barrier

Additional Accessories

The system designer shall specify the above parameters and include even other factors which may be necessary to the design of the expansion joint.

The pipe expansion joint designer will manufacture expansion joints based on the above parameter and also recommend any other field modification in

line with the expansion joint piping system which is necessary.

EJMA and ASME are the most commonly used standards internationally. The piping system must be reviewed to determine the location of anchors, guides and expansion joints.

The structure of the system should be such that the bellows are capable of absorbing the direction and magnitude of the thermal expansion of the piping system.

The bellows material should be compatible with the media to be conveyed at the specified working temperature. The material selected should be resistant to corrosion or erosion which can be caused by the media.

For cases where the external environment is corrosive or reactive, the material selected should be resistant to both inner media and outer environment.

The design pressure of the bellow shall be based on the actual maximum working pressure of the pipeline for a given temperature range. A greater working pressure can result in less flexibility and increased cost.

So, it is important for the client to specify the working pressure which is exactly as per their requirement.

When calculating the movements to be absorbed by an expansion joint, the expansion and contraction of the piping system attached as well as the adjacent vessels, pipe lines, anchors and misalignments caused due to movement need to be considered.

If the movement is cyclic, the number of cycles and the rate of cyclic movements must be considered.

Most commonly used end connections in an Expansion Joint are Flanges and Weld Ends. Specific standards of Flanges and Weld Ends need to be specified at the time of enquiry.

However, if you have a custom requirement, you can specify the same to the manufacturer depending upon your piping requirements.

The need for inner sleeve should be specified. Inner sleeve will depend upon conditions like type of inner media, flow velocity, backflow of media etc.

Need for insulation should be furnished to the manufacturer to properly design the component parts.

If there is a need for additional accessories such as covers, limit rods, thrust rods etc, it should be specified to manufacturer.