Expansion Joint & Bellow Terminology

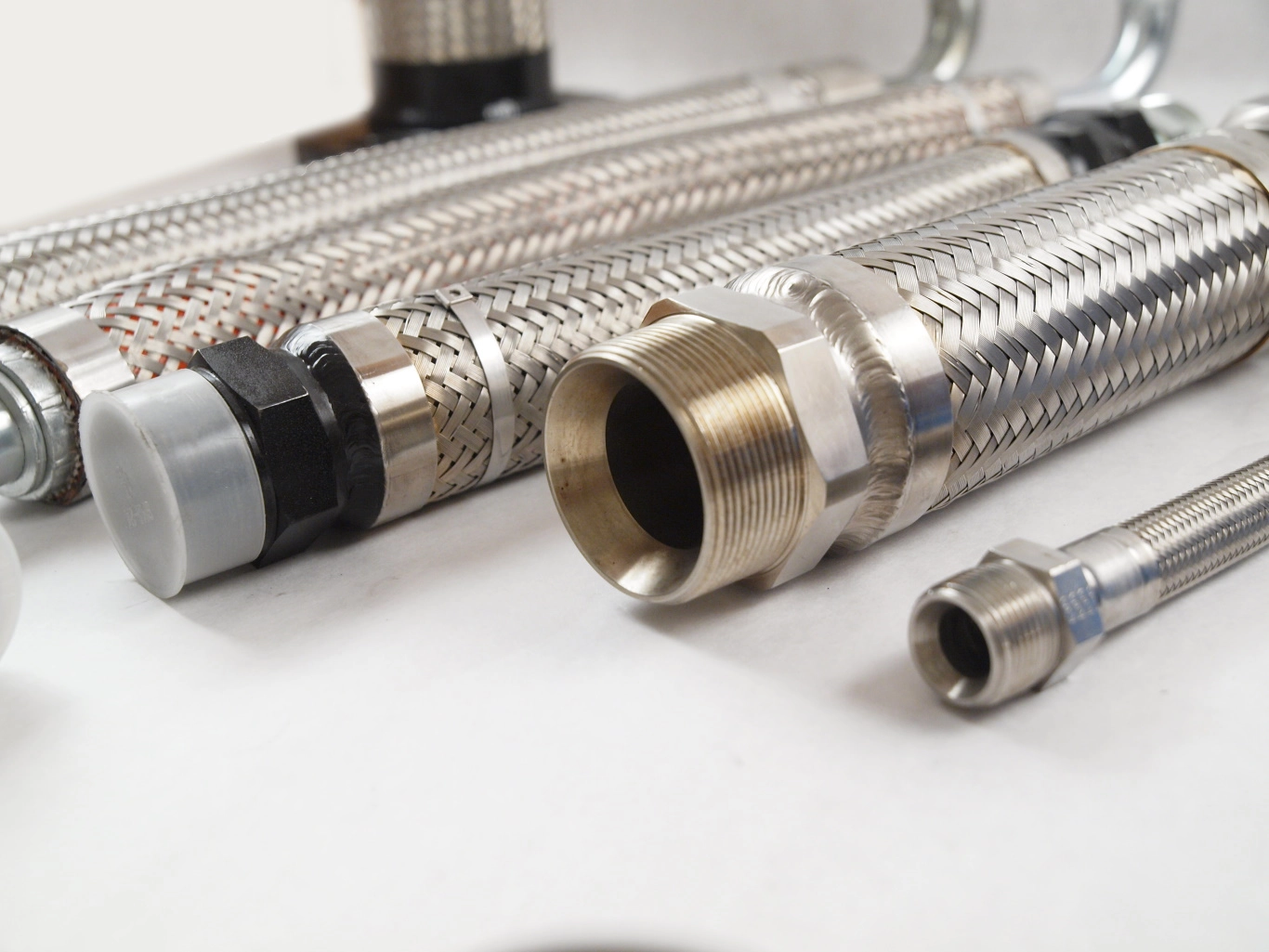

Expansion Bellow & Expansion Joint

Expansion Joint : Expansion joint refers to a metal bellows expansion joint designed to absorb axial, lateral and angular motions in piping systems.

Expansion Bellow : Expansion bellows is the flexible element of an expansion joint. Formed metal bellows are made from tubing by the application of internal pressure. The convolutions are formed in parallel planes that are perpendicular to the longitudinal centerline of the bellows - referred to as annular. The tubing is normally made from sheet or coil that is rolled into a tube and longitudinally welded.

Construction design

Tangents : The straight unconvoluted portions at the ends of the expansion bellows..

Convolution : The smallest flexible unit of a bellows. Each formed shape of the cross section consisting of a root and crest is a convolution or corrugation. With parallel sides the gap at the root and crest are equal, and referred to as "U" shaped. The total movement capacity of a bellows is decided on the base of the convolution design.

End Fitting : A loose term applied to the end assembly or end connection such as nipple, flange, pipe end, weld end, etc., attached to the end of a expansion joint. End Fittings can be welded or brazed to an expansion bellow depending upon the type of application.

Center Spool : The pipe spool that joins the two bellows elements in a Double or Dual Expansion Joint or Universal Expansion Joint.

Collar : A reinforcement used to increase the thickness of the ends of the bellows.

Pipe End / Weld Ends : A tube like pipe section suitable for welding to bellows. A type of end fittings which is welded to the bellows for mating with the pipe system.

Flange Ends : A type of end fittings which is welded to the bellows for further welding to the pipe system or flange end fitting.

Grooved Pipe Ends : A type of end fittings which is in the form a pipe end machined with a groove which can be clamped to the pipe system.

Floating Flange Ends : A flange that is not welded. Normally a back up flange for a Lap Joint Stub or a Van Stone. More convenient for easy installation.

Dimensions

Inner Diameter : The inside diameter of expansion joint corrugation.

Nominal Diameter : The approximate diameter of the expansion joint corresponding to the NPS.

Overall Length / End to End Length : The length of the expansion joint assembly into account the end fittings.

Outer Diameter : The outer diameter of the expansion bellow convolution.

Fitting Inner Diameter : The inner diameter of the end fittings.

Convoluted Length / AL : The convoluted length is measured between the centers of the radii of the end convolutions.

Pressure & Temperature

Design Pressure : The maximum pressure at which a expansion joint is designed to be used. This should be greater than or equal to the working pressure.

Working Pressure : The pressure, usually internal but sometimes external, imposed on an expansion joint during operating conditions. Both internal and external pressure need to be mentioned when placing an enquiry.

Test Pressure : The maximum internal pressure which an expansion joint can be subjected to without permanently deforming the corrugations. Test Pressure is greater than the design pressure.

Burst Pressure : A burst value which may be theoretical, or a percentage of the actual burst pressure developed by a laboratory test. Burst Pressure is greater than the Test Pressure.

Deformation Pressure : The pressure at which the convolutions of a expansion joint become permanently deformed. Deformation Pressure is greater than the Burst Pressure.

Pulsating Pressure : A rapid change in pressure above and below the normal base pressure, usually associated with reciprocating type pumps.

Vacuum : Negative pressure or suction.

Ambient Temperature : The ambient temperature is the temperature of the environment to which the expansion joint is exposed.

Working Temperature : The temperature, usually internal but sometimes external, imposed on an expansion joint during operating conditions.

Movement and Motion

Axial Movement : Axial Movement occurs when the elongation or compression of the pipe system is along its longitudinal axis.

Lateral Movement : Motion that occurs when one end of the expansion joint is deflected in a plane perpendicular to the longitudinal axis with the end remaining parallel.

Angular Movement : Motion that occurs when one end of the expansion joint is deflected at a simple angle with the ends not remaining parallel.

Radial Motion : Motion that occurs when the centreline of the assembly is bent in a circular arc.

Thermal Expansion : Most metals expand when they are heated and contract as they are cooled. This is a property that is unique to each metal and metal alloys which varies for different temperature ranges.

Axial Spring Rate : The force required to compress or extend the ends of a bellows with the longitudinal centerline straight and the ends parallel.

Lateral Spring Rate : The force required to displace (offset) the longitudinal centerline of a bellow with the ends parallel.

Angular Spring Rate : The displacement of the longitudinal centerline of a bellows from a straight line into a circular arc.

Rated Movement : The maximum amount of movement (axial extension, axial compression, lateral deflection, angular rotation, or any combination thereof) which a pipe expansion joint is capable of absorbing.

Vibration : Low amplitude motion at high frequency

Torque ( Torsion ) : Excessive twisting of the assembly causing metal fatigue and failure.

Life Cycle / Fatigue Life : The cycle life or fatigue life expectancy of a bellows is based on the number of complete pressure and displacement cycles that result in metal failure.

Media, Medium : A gas or liquid or solid medium to be conveyed within the expansion bellow or expansion joint.

Attachment Techniques

Lap Weld : Type of weld in which the ends or edges of the metal overlap each other.

Butt Weld : The joint formed by placing two pieces of metal end-to-end and then welding along the join.

GTAW / TIG : Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld

GMAW : Gas Metal Arc Weld. In the GMAW process, an electric arc is formed between the metal and a wire electrode, applying heat to the metal pieces.

Brazing : Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature.

Additional Accessories

Inside lining / Inner Sleeve : Flow liners fit inside of an expansion joint, allowing internal fluids to pass without excessively vibrating the pipe system. These features are especially important when fluids travel at high velocities, threatening to cause damaging resonant vibrations.

External Casing / Outer Cover : A shield or shroud that covers the outside surface of a bellows to provide protection from mechanical damage or arc strikes. Can also be used to retain external insulation for some applications.

Control Rod : Devises normally made from rod or bar installed to limit the travel of each individual bellows in a universal expansion joint to the rated motion. Control rods are not designed to react pressure thrust.

Gasket : A non-porous deformable material that is installed between the belt attachment flange and the fabric belt. The gasket allows a gas-tight seal when the back-up bar clamping action is applied.

Tie Rod : Devices, usually in the form of rods or bars, attached to the pipe expansion joint assembly whose primary function is to continuously restrain the full pressure thrust during normal operation while permitting only lateral deflection. Angular rotation can be accommodated only if two tie rods are used and located 90 degrees as opposed to the direction of rotation.

Other terms

Application : The service conditions that determine how an expansion joint will be used.

Anchor : A restraint applied to a pipeline to control its motion caused by thermal growth.

Ply, Plies: The number of individual thicknesses of metal used in the construction of the wall of an expansion joint.

Scale : Generally refers to the oxide in a expansion joint brought about by surface conditions or welding.

Corrosion : The chemical or electro-chemical attack of a media upon an expansion joint.

EJMA : An organization that publishes the Standards of the Expansion Joint Manufacturers Association, the worldwide standard for metal bellows expansion joint design.

ASME : An expansion joint manufactured to one of the American Society of Mechanical Engineers Codes.