Designed as per ISO 10380

Why choose Ocelflex Corrugated Stainless Steel Metal Hoses?

Ocelflex Industries is a manufacturer of corrugated metal hose, braid and its assemblies. Ocelflex has more than 35 years of experience in providing flexing

solutions to various industries.

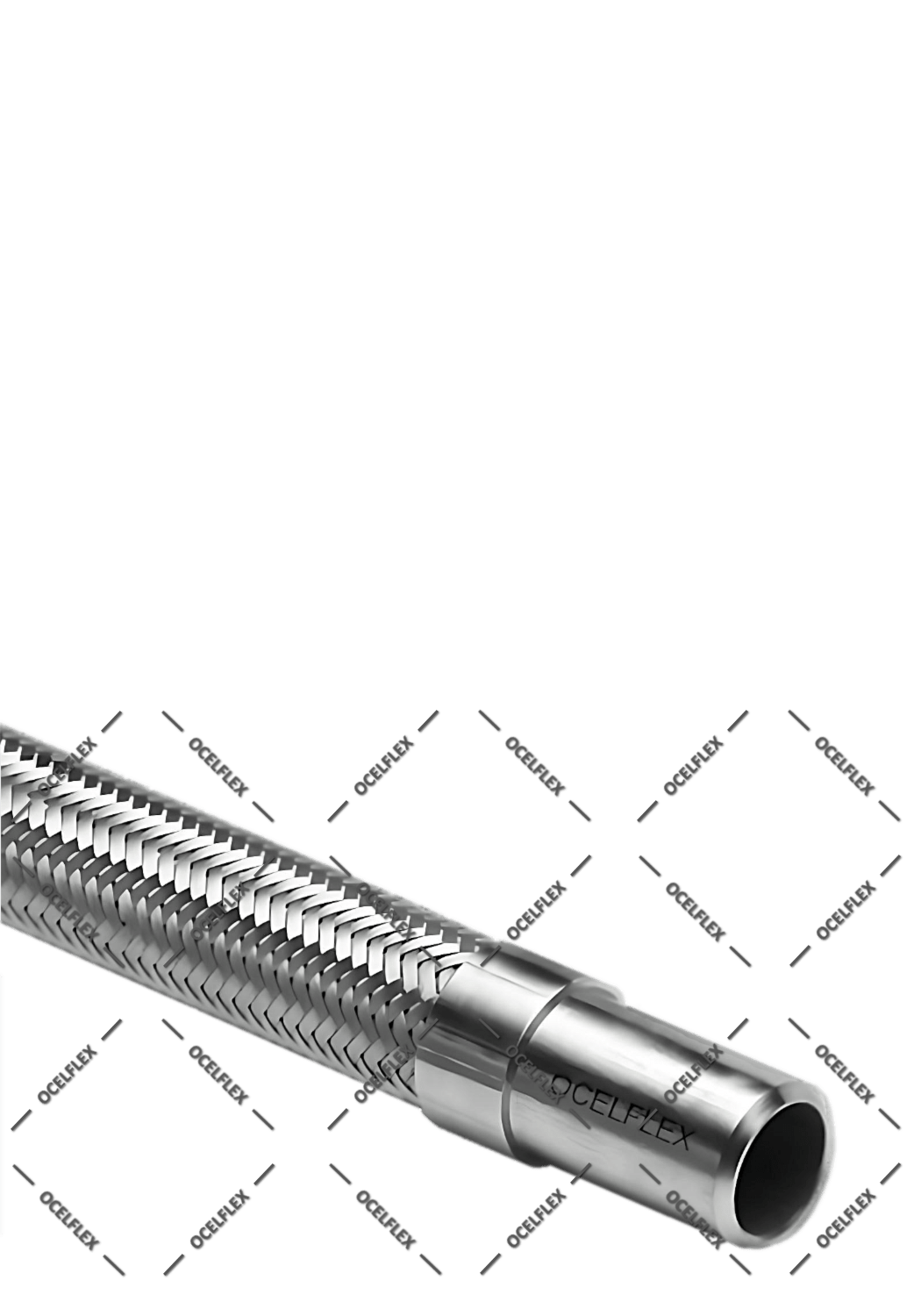

We offer a wide range of metal hoses, with and without metal braid, for nearly any liquid and gaseous transfer application.

High flexibility, high temperature resistance, high pressure ratings and suitability for a wide variety of media, are some reasons for its increasing demand in

food and chemical, medical and pharmaceutical, oil and gas, construction and ship building, glass, aerospace, power, railway, and automotive industries.

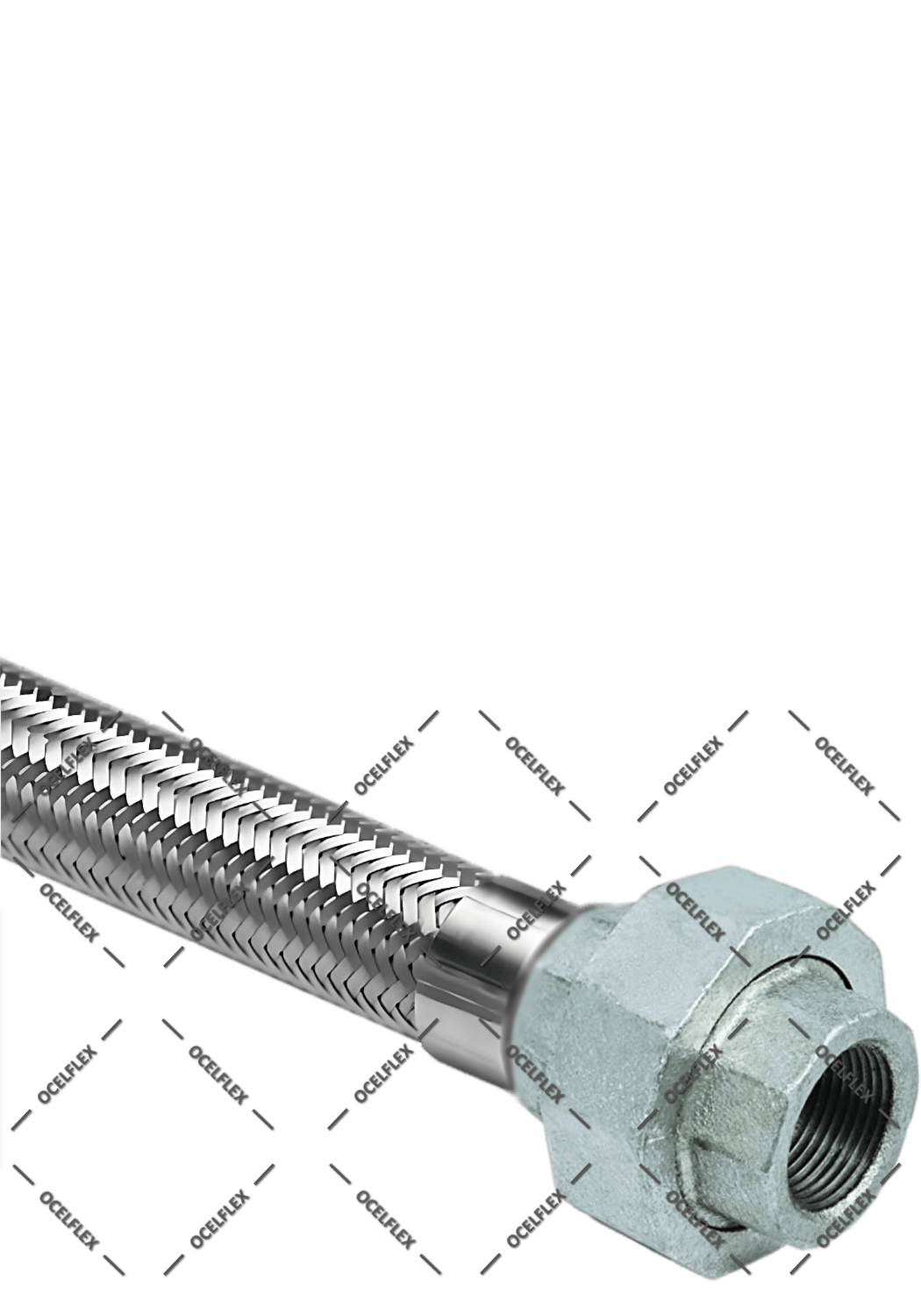

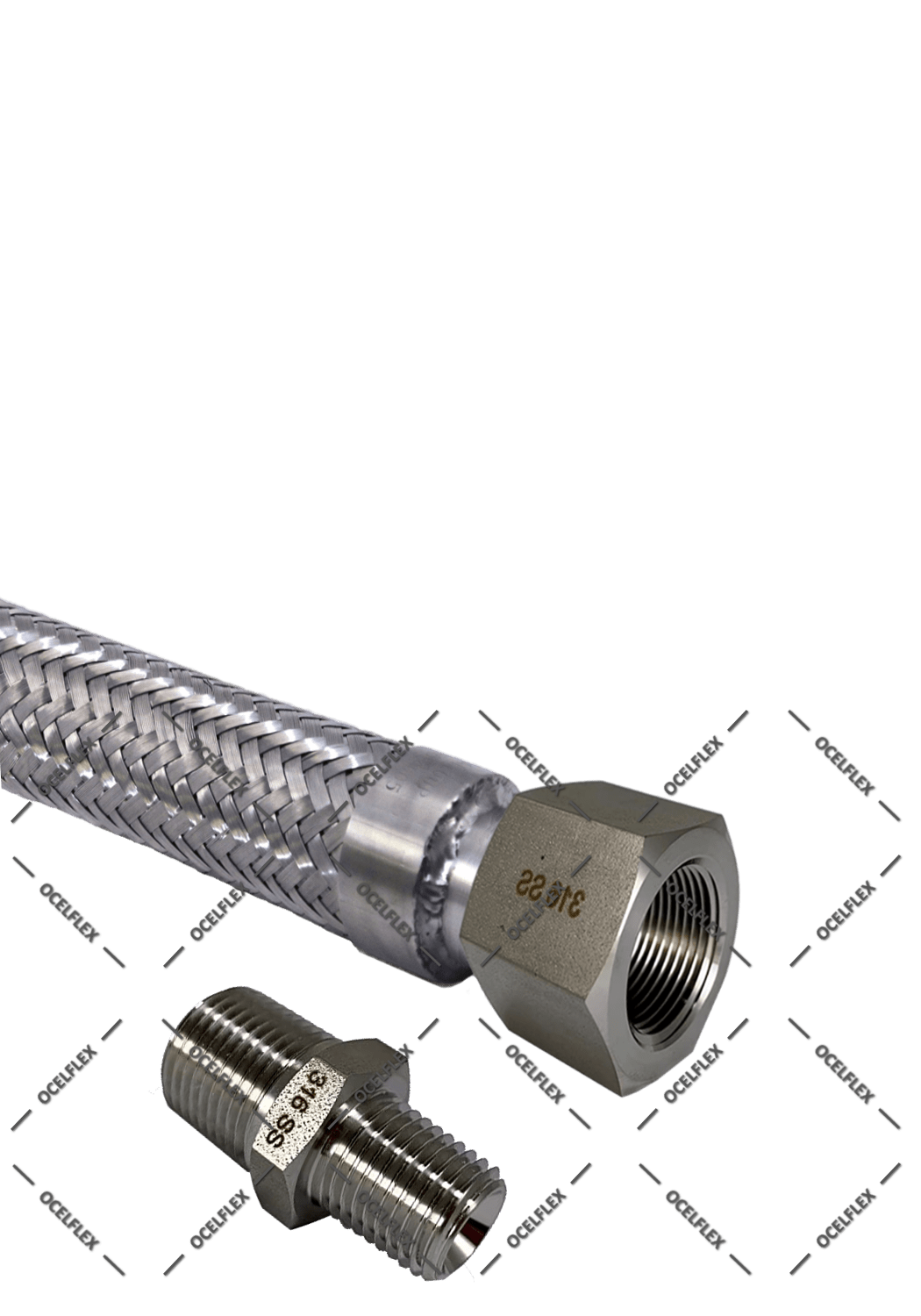

A metal hose assembly is composed of the inner corrugated hose element, with outer braid/s and end hose connectors. Few advantages of flexible metal hoses :

- Wide range of Materials : Stainless Steel 316, Stainless Steel 316L Stainless Steel 321, Stainless Steel 304, Stainless Steel 304L.

- Suitable for wide temperature ranges from - 270 ℃ to 700 ℃.

- Preffered for vacuum and high pressure applications - for pressures upto 200 bar.

- Suitable for adjusting misalignment and absorbing minor vibrations.

Our design, quality raw material and precision manufacturing ensures maximum cycle life of the hose, at most competitive rates.