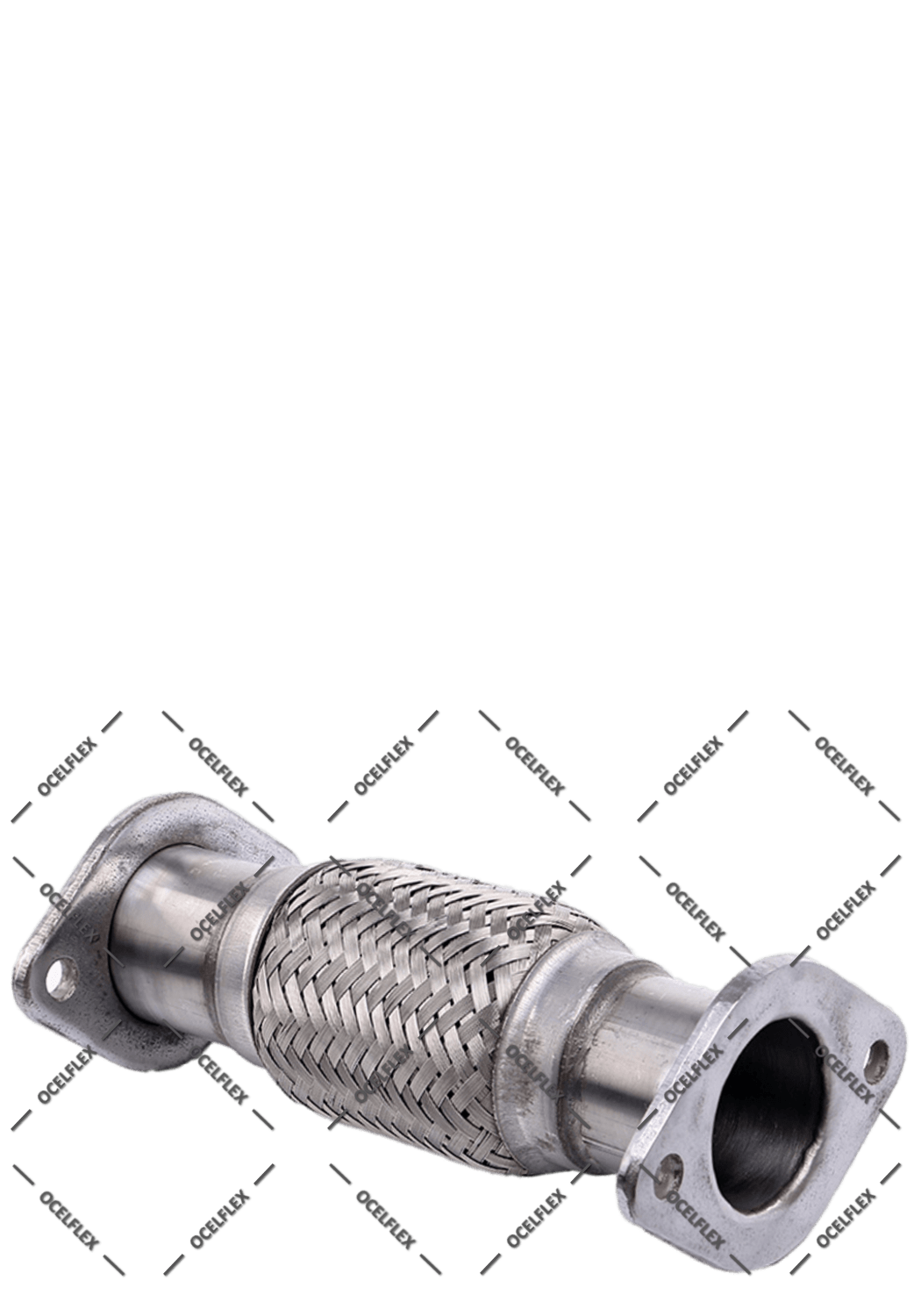

Receive a quote for your requirement of Automotive Exhaust Flexible Connector.

Let our experts help you!

To discuss your hose or expansion joint requirements, complete our convenient form and we’ll get in touch with you at the earliest.

Have an urgent deadline to meet? Choose Express Manufacturing!

With more than 35 years of experience in manufacturing hoses and expansion joints, at Ocelflex, we have sufficient inventory and manufacturing capability to meet your crucial timeline. Just inform us of your need for Express manufacturing when sending us your requirement.